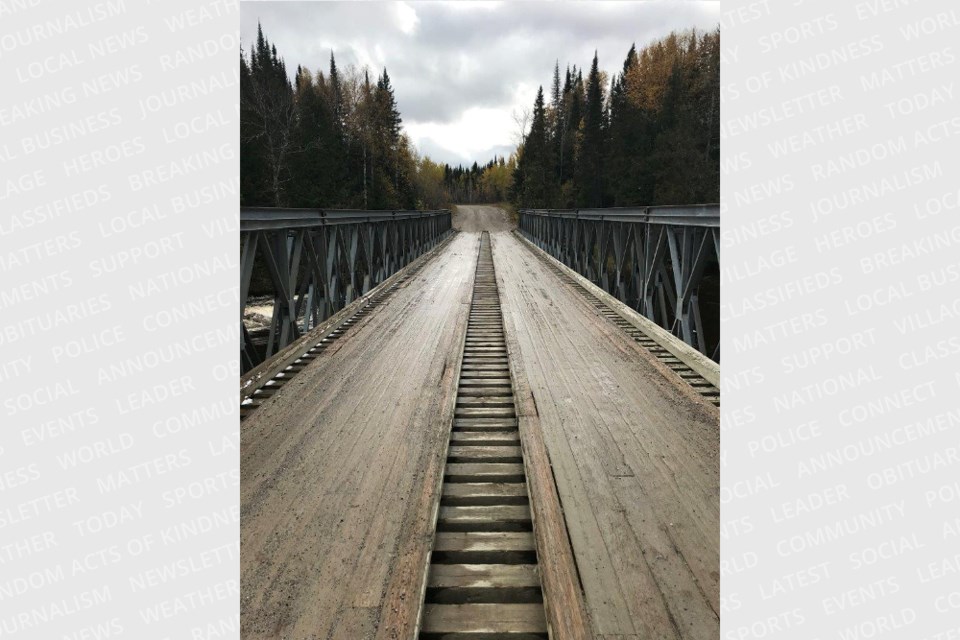

There could be a certain smell from the zinc but there is a definite sound when you cross this bridge. There are many on the back roads of Northern Ontario.

Is that the sound of the 'trit-trot, trit trot' of The Three Billy Goats Gruff crossing the galvanized steel and timber deck planks creating the discernible rumble or what engineers term 'impact noise'?

Beyond the smell and sound of the bridge, it is the Grade Nine geometry and the history behind the Bailey bridge that deserves recognition.

Geometry and structure

First off, the design and structure of the Bailey bridge have to be appreciated especially all of those triangles.

Jean-Paul (JP) Chiasson Director of Engineering - Cementation Americas (mining) was contacted in North Bay.

"Interestingly, in the early part of my career, I inspected and assessed a number of Bailey bridges – most of them were used on timber or power line access roads. Apparently, they also work to carry pickup trucks and campers."

“The primary advantage of the Bailey Bridge concept is that, with an inventory of key components and the assembly manual, bridges can quickly be constructed for a wide variety of spans, design loads and lane widths," Chaisson said. "Structurally, the main bridge components are the truss panels, deck stringers, deck components and several types of pins, braces, base plates and chord reinforcements.

“Most People’s eyes will glaze over when they read the description of the truss type, but maybe a couple of structural engineers will quibble over my description,” he added with a chuckle.

It is worth knowing what makes us safe when we cross over a Bailey bridge.

“The symmetrical arrangement of squares and triangles in the Bailey truss panels are pleasing to the eye – one suspects not a structural engineer, but an artist at work here," said Chaisson. "Nevertheless, each component has been carefully selected to optimize the structural capacity of the truss. The top chord is in compression, the bottom chord is in Tension, while the forces in the web members alternate between tension and compression to distribute the shear effects between the top and bottom chords.

“The truss panels are truly the heart of the bailey bridge system and the reason for its flexibility. Five feet tall and 10 feet long, each panel is comprised of structural steel components, welded together to form a consolidated unit. Each unit is comprised of double-channel top and bottom chords, three vertical I-beams and I-beam braces. The Bailey truss can be described as a truncated flat two-way intersection Howe truss.

“By joining the panels together, the truss length can be adjusted between 10 feet to 120 feet in length. By placing two trusses side by side, the capacity of the bridge can be doubled. By stacking the trusses one on top of the other, and adding top and bottom chord reinforcements, the capacity of the bridge can be increased further. The manual provided by the manufacturer provides tables that define the bridge capacity for all of the commonly used spans and configurations.”

Despite the ease of designing a Bailey bridge, a professional engineer must still certify the design of the bridge abutments, the required load rating of the bridge, and confirmation of the final Bailey bridge configuration and component selection.

Why don’t we see more Bailey bridges?

“For one thing, it might not always represent the most efficient use of materials, depending on the span and use, Chaisson said. "For shorter spans, the Bailey truss is stronger than it needs to be and would be heavier than using standard structural steel beams.

"For 120 ft. spans, the need to stack the trusses is also relatively inefficient compared to custom built-up girders, or other materials. For two-lane (the practical limit) use, the inefficiency is compounded, and the maximum span is further limited. In addition, for permanent use in heavy traffic areas, the bridges require a lot of maintenance – all of those pins and braces can loosen over time and require constant tightening. Also, in urban settings because 'anyone can build one,' 'anyone can take one apart' using common tools, so Baileys are prone to vandalism and theft of the components.”

The bridges are galvanized, (zinc) hence the grey colour. Galvanizing is used to protect the steel from corrosion and extend the life of the bridge.

Military history

“The continued Is a testament to the design and versatility of the Bailey bridge, many Bailey bridges are in use around the world today – some 80 years after its introduction in 1942. Some of the oldest can be found in Canada.”

So, says LCol. Ken Holmes, CD (Ret'd), Canadian Military Engineer Historia, Vice President, History and Heritage, Canadian Military Engineers Association.

The Bailey bridge was designed by Sir Donald Bailey during WWII to be built by hand yet carry the modern tank.

Bridging equipment remaining from WW I did not have the load capacity and those designs could not be upscaled.

“Bailey’s design was based on only 17 components – the heaviest of which was the Panel that weighed 570 lbs and could be carried by six soldiers," Holmes said. "An engineer troop of 40 men could assemble an 80-foot bridge in four hours by day and eight hours at night. Long spans of a multi-storey design of up to 150 ft could carry a heavy tank.

“The Bailey bridge was acknowledged by General Eisenhower as one of the three war-winning inventions during WWII.”

During WWII, the Allies built some 4,500 Bailey Bridges in Europe.

“As the war in the Far East progressed, Bailey bridges were constructed in Burma, India, and Nepal by the British, the Americans, and the Australians,” said Holmes.

The first Bailey bridge erected under enemy fire was built by the Royal Canadian Engineers at Leonforte, Sicily during the nights of July 22 to 24 in 1942.

Following the end of WWII, Bailey bridge stock in the UK and Europe was disposed of locally in the local countries.

“Much of the surplus Canadian Bailey bridge inventory was sold in Canada to public sector organizations such as provincial ministries of transportation, the Ontario Hydro-electric Power Commission as well as private sector companies.”

Bailey bridges continued to be used extensively by military forces after the war until newer equipment was introduced to meet the more demanding needs of modern warfare.

“Components built to the original specifications are still being manufactured, however, and find regular use in less-developed countries or for emergencies. Modern variants are also common.”

After the war, Bailey bridges continued to be built throughout Canada.

“To this day, many small communities rely on the Canadian Military Engineers to construct temporary Bailey Bridges to replace bridges destroyed by natural disasters or to build permanent bridges to span gaps on small roads and trails,” Holmes added.

One of the oldest public sector Bailey bridges is the Old Finch Avenue Bridge in Toronto over the Rouge River.

“It was built in 1954 after flooding from Hurricane Hazel severely damaged or completely washed out several bridges. The Royal Canadian Engineers constructed a Bailey bridge within 24 hours.”

Overseas Deployment

And Bailey bridges remain a mainstay with the Canadian Armed Forces.

Capt Nicholas Marshall is with the 25 Support Squadron 2IC, 2 Combat Engineer Regiment, Canadian Armed Forces, based in Petawawa.

He first acknowledged the bridge's historic significance.

“The Bailey bridge has had enormous success within Allied militaries, including Canada’s. It was designed to be erected, moved, rebuilt, or replaced using immediately available engineering resources within a few hours," Marshall said. "During World War II (WWII), more than 4500 Bailey bridges were constructed by Allied forces in Italy and Northwest Europe."

Capt. Marshall said, “Referencing the use of these bridges during WWII, British Field Marshal Bernard Law Montgomery said it best: “without the Bailey bridge, we should not have won the war. It was the best thing in that line we ever had.”

The rapidly deployable bridges allowed Allied armies to remain highly mobile and capable of pursuing retreating forces. Canadians constructed the longest Bailey Bridge of the war. The Blackfriars Bridge, built over the Rhine River in 1945 by Royal Canadian Engineers, measured 558 meters. Donald Bailey, the inventor, was knighted in 1946 for his contribution to the Allied victory.

Its effectiveness and versatility were not limited to the battlefield. Several permanent Bailey Bridges are still in use throughout Canada today – some 80 years after its introduction.

The Canadian Armed Forces used the Bailey bridge for some 50 years before replacing it with newer alternatives. The Bailey Bridge allowed engineers to construct bridges strong enough for tanks to cross using components that could be put into place by a single soldier or a small group. Currently, within the Canadian Army, the concept of the Bailey bridge is still being used through variants such as the ACROW Bridge and the Medium Girder Bridge (MGB).

More on Bailey

A Bailey bridge and its flexible construction were prominently featured in the 1977 film A Bridge Too Far.

Norgalv is a hot-dip galvanizing plant within the North Bay mining sector.

See the replacement of the Dokis First Nation access bridge over the Restoule River there are some good photos.

A good YouTube military video showing contemporary construction.

If you want to purchase a Bailey bridge see the Agico Group - there are good design graphics and photos on the website.

“The MTO has 40 Bailey bridges in the Northeast region,” says Justin Bryant the MTO’s Communications Coordinator, Northeast Operations-Regional Services and Relationships Office.

Contact Back Roads Bill and send a photo of your favourite Bailey bridge, and the location list will be expanded. Here’s a map link for some of the locations. you can add a pin location for your contribution.

Bailey bridges remind me of The Three Billy Goats Gruff story. It is about three goats, each one bigger than the next.

The goats want to cross a bridge that is owned by a troll, but the troll won't let them pass. The troll says he wants to eat them up. The goats trick the troll so they can cross the bridge with a tragic ending.

Watch for trolls and oncoming traffic on the back roads, especially when approaching this one-lane marvel.