NEWS RELEASE

NEWS RELEASE

SUPERIOR COPPER INC.

*************************

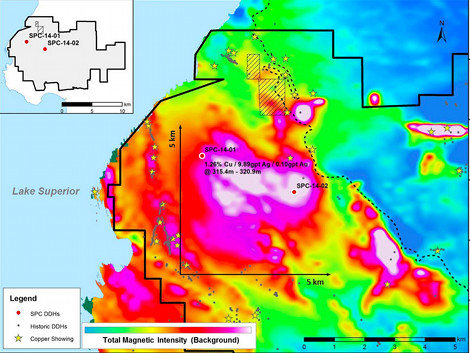

Superior Copper Corporation (“Superior Copper” or the “Company”) is pleased to announce that it has discovered a new zone of copper-silver-gold mineralization on its 100%-owned Superior Project. Diamond drill hole SPC-14-01 intersected this new mineralized zone at 315 metres (“m”), which is deeper than any previous work done anywhere on the property.

No previous drilling has occurred within 1.7 kilometres (“km”) of this drill hole.

SPC-14-01 was drilled vertically at UTM 16T 5212800mN, 671750mE to a total depth of 951.7 m.

Mineralization occurs as disseminated to semi-massive chalcocite in a fault bounded hydrothermally altered Keweenawan basalt unit.

Additional drilling is needed to determine the attitude of the copper-bearing zone.

With this discovery, the Company’s management has decided to retain a second drill rig to continue to develop this new mineralized zone.

The original diamond drill rig will continue on iron-oxide-copper-gold (“IOCG”) targets identified by Superior’s geologists and geophysical surveys as previously announced in the Company’s news release on June 3, 2014.

On Site Quality Assurance / Quality Control Measures

The aforementioned assay and sample information, as well as geological descriptions are taken from the drill log as prepared by Miron Berezowsky, P.Eng. Mr. Berezowsky has over 40 years of field experience in a host of geological settings around the world and is a Senior Geological Consultant for Superior Copper.

All samples reported upon herein were selected, and sealed and readied for shipment to ALS Minerals preparation laboratory in Sudbury, Ontario. Sample intervals were selected and cut in half by diamond core saw.

Individual samples were labeled, placed and sealed in plastic sample bags.

Groups of samples were then placed into durable rice bags that were secured.

The rice bags were then delivered via a bonded courier to the ALS sample preparation laboratory in Sudbury, Ontario.

All samples were then crushed and pulverized using ALS preparation procedure PREP-31.

The sample pulps were sent to ALS Laboratory in Vancouver B.C. for analysis.

In Vancouver, the samples underwent analysis using ALS assay procedure ME-MS61r, a 60 element four acid ICP-MS multi-element package which includes Rare Earth Elements.

When samples received over-limit values they underwent further analysis using ALS assay procedure ME-OG62 (for copper).

All samples were also analyzed using ALS assay procedure Au-AA23 gold.

The reader is referred to: www.alsglobal.com for details of these analytical procedures.

Independent Quality Assurance and Quality Control Protocol

A comprehensive QA/QC program has been implemented to monitor all assays on the Superior Project. Samples are assembled in numbered batches of 35 samples.

Included in each batch of 35 samples are 2 certified reference material samples, 1 blank sample comprised of sterile sand, and 2 field duplicate samples.

This QC program was implemented by Tracy Armstrong P.Geo, for Superior Copper.

Ms. Armstrong is a qualified geologist in the 1 / 32014 Releases

Provinces of Ontario, Quebec and British Columbia.

Assay results will be monitored on an on-going, real time basis for accuracy, contamination and precision by Ms. Armstrong.

About Superior Copper Corporation

Superior Copper Corporation is a Canadian-based exploration company focused on base and precious metal exploration.

The Company’s primary objective is to target highly prospective and underexplored mineral properties, particularly copper, in order to meet the continual global demand.

Its primary land position is its 100%-owned Superior Project, which covers 15,789 hectares or 158 square km, and is located approximately 85 km north of Sault Ste. Marie, Ontario.

The technical aspects of this press release have been reviewed by D. Morgan Quinn, P.Geo., who is the “Qualified

Person” as defined by NI 43-101 for this project.

*************************