A University of Guelph student who last year won a prize for his low-cost 3D printed prosthetic hand for children will travel to India next week to bring his design to more people in need.

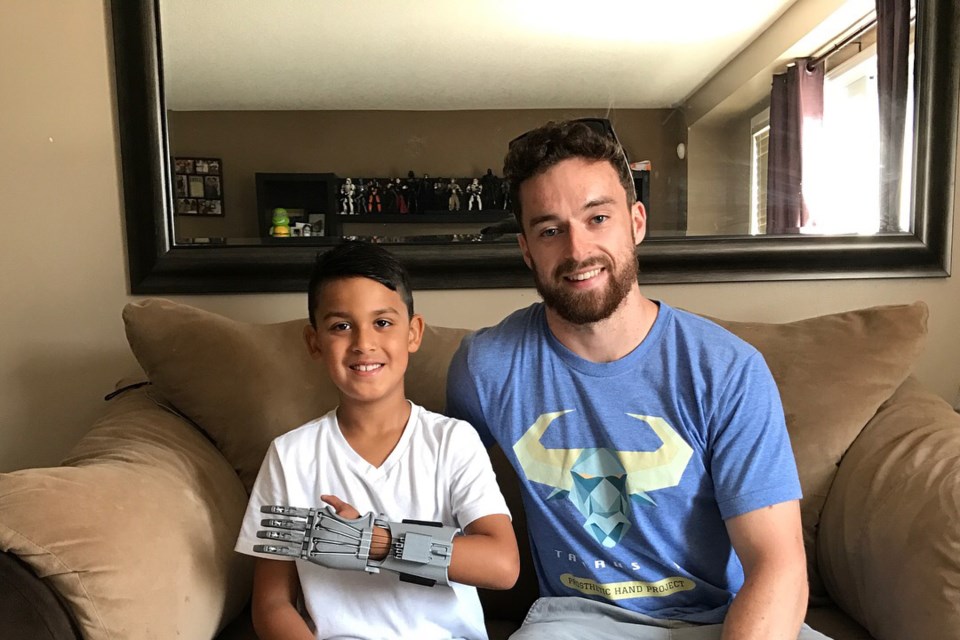

Jerry Ennett is a fifth-year Biomedical Engineering student who has been perfecting his design for the prosthetic hand for about three years.

“A young girl came to us through a professor who needed a prosthetic and couldn’t afford a regular one. We designed one, found some stuff online about 3D printing and then began printing it,” said Ennett.

After the success of that design, Ennett began getting requests from other children, some with no hand at all, some with no fingers or thumb and others with only a thumb.

“I was shocked at how many (kids) needed it,” said Ennett.

With some design changes, Ennett is able to modify his model for different needs and each hand costs about $25 in materials.

“The good thing with 3D printing is they can be customized pretty easily and they are very inexpensive to manufacture,”said Ennett.

With the 3D printed prosthetic, Ennett said, children are able to grasp items, throw, ride their bike or play at the playground.

“By flexing their wrist they are able to activate the hand and open and close the fingers,” he said.

Last year, Ennett’s 3D printed prosthetic won the 2016 World Vision Social Innovation Challenge, which led to him being invited to Amar Seva Sangam, a rehabilitation centre in India.

Next week, Ennet will travel to the centre with a 3D printer in tow.

“They told me they see about 20 amputees a month and have no ability to make prosthetics, they have to send them on a two-day trip to the nearest centre that does have them,” said Ennett.

The plan is to not only make prosthetics for the children who come during his visit, but to leave the printer there and train the professionals at the centre to become a self-sufficient manufacturer of his designs.

“If they see an issue, they can email me a photo of it or a 3D scan of the patient and I can design it here and email it back and they can just print it off,” said Ennett.

Shortly after Ennett designed his first prosthetic in his second year, he used a summer business grant in his hometown of Stratford, Ont. to buy his first 3D printer and start his company, called Taurus 3D.

Depending on the success of the trip to Amar Seva Sangam, Errett said his company will continue the work and possibly expand to other areas in need.

“If the need is there and the clinic enjoys the benefits, I will probably be dedicating my time to outfitting other clinics,” he said.